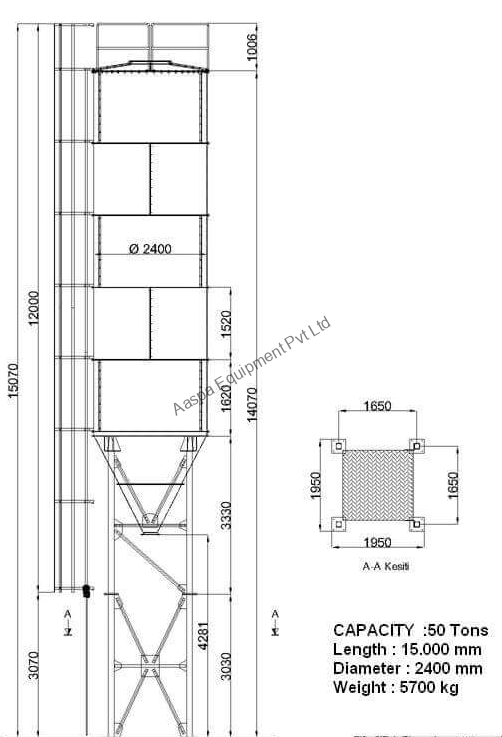

Vertical Storage Silo AS-50

AASPA 50 tones capacity cement silo AS-50 has a wide range of usage area from concrete plants to block machines and also ground study applications. AS-50 can be manufactured as bolted or welded type. 2 sets of the bolted version of AS-50 can be shipped within 1 pcs 40 ft OT container or a truck.

AASPA AS-50 cement silo is equipped with maintenance platform between the legs, cement filling pipe, inner and outer manholes, safety guards, roof flanges for the air filter and pressure safety valve, a roof gate for inner manhole and also a cone flange for butterfly valve.

AASPA AS-50 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging.

In case of manufacturing the bolted type version, parts of cement silos are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 50 TONS, 38 m3 |

| Silo Height | 15000 mn |

| Silo Diameter | Ø 2400 mm |

| Quantity Of Silo Legs | 4 |

| Silo Output Diameter | Ø 300 mm |

| Number Of Components | 8 |

| Silo Weight | 6160 Kg |

| Material Of Silo Legs | 168 x 5 mm, STEEL PIPE |

| Supports Of Silo Leg | NPL 60 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 15 mm SHEET METAL |

| Conical Part Support Material | 100 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 – 5 mm SHEET METAL |

| Silo Body Material | ST – 37 – 4 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 – 4 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

Layout

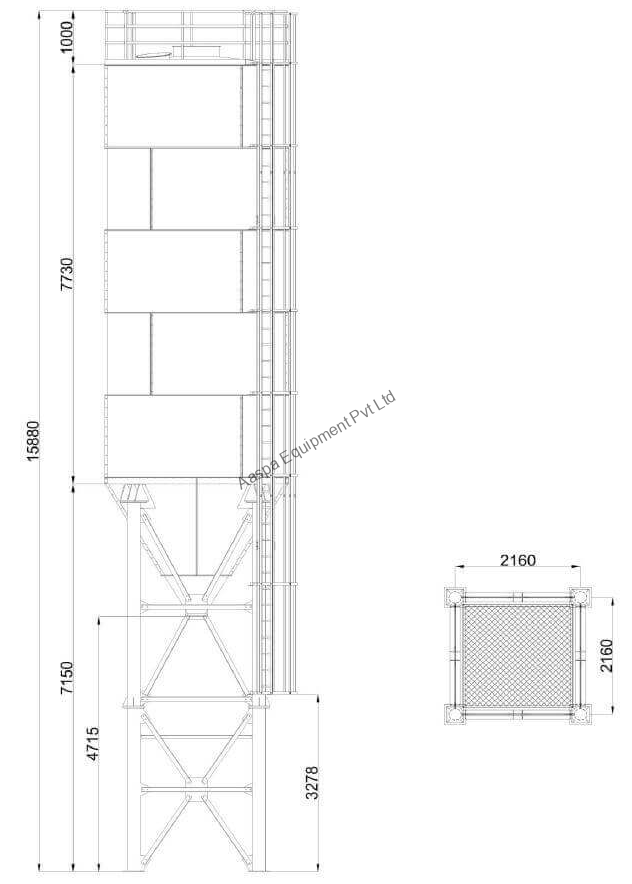

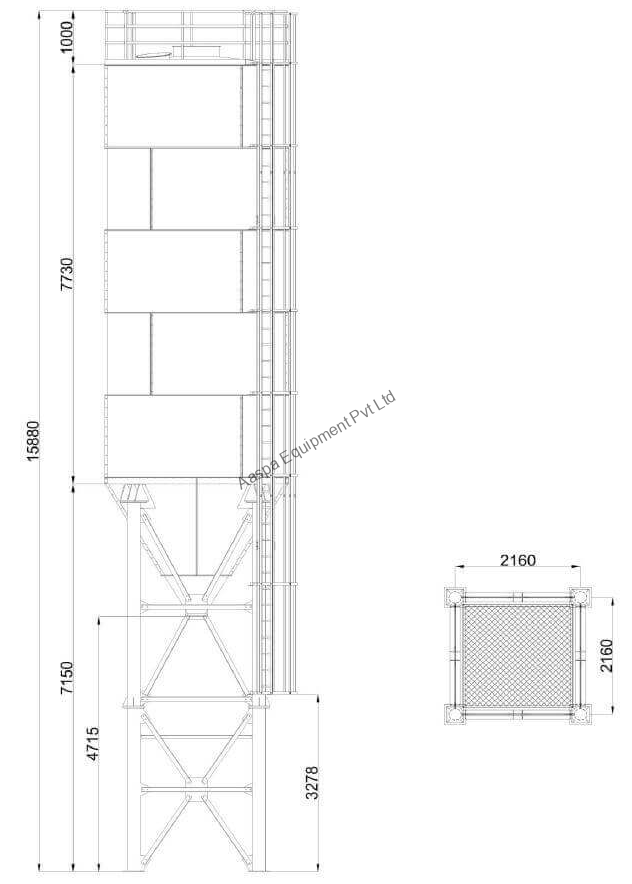

VERTICAL STORAGE SILO AS-75

AASPA 75 tones capacity cement silo AS-75 has a wide range of usage area from concrete plants to block machines and also ground study applications. AS-75 can be manufactured as bolted or welded type. 2 sets of bolted version of AS-75 can be shipped within 1 pcs 40 ft OT container or a truck.

AASPA AS-75 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging.

In case of manufacturing the bolted type version, parts of cement silos are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 75 TONS, 58 m3 |

| Silo Height | 15880 mn |

| Silo Diameter | Ø 3060 mm |

| Quantity Of Silo Legs | 4 |

| Silo Output Diameter | – |

| Number Of Components | 98 |

| Silo Weight | 6360 Kg |

| Material Of Silo Legs | 219 x 5 mm, STEEL PIPE |

| Supports Of Silo Leg | NPL 80 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 20 mm SHEET METAL |

| Conical Part Support Material | 100 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 -6 mm SHEET METAL |

| Silo Body Material | ST – 37 – 5 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 – 4 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

Layout

Vertical Storage Silo AS-100

AASPA 100 tones capacity cement silo AS-100 has a wide range of usage area from concrete plants to block machines and also ground study applications. AS-100 can be manufactured as bolted or welded type. 2 sets of bolted versions of AS-100 can be shipped within 1 pcs 40 ft OT container or a truck.

AASPA AS-100 cement silo is equipped with maintenance platform between the legs, cement filling pipe, inner and outer manholes, safety guards, roof flanges for air filter and pressure safety valve, a roof gate for inner manhole and also a cone flange for butter fly valve.

AASPA AS-100 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging.

In case of manufacturing the bolted type version, parts of cement silos are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 100 TONS, 78 m3 |

| Silo Height | 18900 mn |

| Silo Diameter | Ø 3060 mm |

| Quantity Of Silo Legs | 4 |

| Silo Output Diameter | Ø 300 mm |

| Number Of Components | 120 |

| Silo Weight | 8000 Kg |

| Material Of Silo Legs | 219 x 5 mm, STEEL PIPE |

| Supports Of Silo Leg | NPL 80 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 20 mm SHEET METAL |

| Conical Part Support Material | 100 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 – 6 mm SHEET METAL |

| Silo Body Material | ST – 37 – 5 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 – 4 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

Layout

Vertical Storage Silo AS-200

AASPA 200 tones capacity, bolted type cement silo AS-200 is preferred especially in high capacity concrete batching plants and also in projects that cement stocking has a critical role.

AASPA AS-200 cement silo is equipped with maintenance platform between the legs, cement filling pipe, inner and outer manholes, safety guards, roof flanges for air filter and pressure safety valve, a roof gate for inner manhole and also a cone flange for butter fly valve.

AASPA AS-200 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging.

Parts of AS-200 bolted type cement silo are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 200 TONS, 153 m3 ( cement density as 1,3 ton/m3 ) |

| Silo Height | 18360 mn |

| Silo Diameter | Ø 4100 mm |

| Quantity Of Silo Legs | 4 |

| Silo Output Diameter | Ø 300 mm |

| Number Of Components | 150 |

| Silo Weight | 14800 Kg |

| Material Of Silo Legs | 200 x 2 mm, RECTANGULAR IRON |

| Supports Of Silo Leg | NPL 80 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 20 mm SHEET METAL |

| Conical Part Support Material | 140 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 ,8 mm SHEET METAL |

| Silo Body Material | ST – 37, 5 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 , 4 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

| painting : 1 layer of anticorrosive paint, 2 layer of final coat epoxy paint, total paint thickness: 140 microns. | |

Layout

VERTICAL STORAGE BOLTED SILO AS-300

AASPA 300 tones capacity, bolted type cement silo AS-300 is preferred especially in high capacity concrete batching plants and also in projects that cement stocking has a critical role.

AASPA AS-300 cement silo is equipped with maintenance platform between the legs, cement filling pipe, inner and outer manholes, safety guards, roof flanges for air filter and pressure safety valve, a roof gate for inner manhole and also a cone flange for butter fly valve.

AASPA AS-300 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging.

Parts of AS-300 bolted type cement silo are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 300 TONS, 230 m3 ( cement density as 1,3 ton/m3 ) |

| Silo Height | 18450 mn |

| Silo Diameter | Ø 5140 mm |

| Quantity Of Silo Legs | 6 |

| Silo Output Diameter | Ø 300 mm |

| Number Of Components | 191 |

| Silo Weight | 22000 Kg |

| Material Of Silo Legs | Ø273 x 10 mm, STEEL PIPE |

| Supports Of Silo Leg | NPL 80 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 20 mm SHEET METAL |

| Conical Part Support Material | 200 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 ,8 mm SHEET METAL |

| Silo Body Material | ST – 37, 8-6-5 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 , 5 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

| painting : 1 layer of anticorrosive paint, 2 layer of final coat epoxy paint, total paint thickness: 140 microns. | |

Layout

VERTICAL STORAGE BOLTED SILO AS -500

AASPA 500 tones capacity, bolted type cement silo AS-500 is used in very high capacity concrete batching plants which have high amount of cement consumption and also in cement terminals, cement factories and limestone powder stocking applications.

AASPA AS-500 cement silo is equipped with maintenance platform between the legs, cement filling pipe, inner and outer manholes, safety guards, roof flanges for air filter and pressure safety valve, a roof gate for inner manhole and also a cone flange for butter fly valve.

AASPA AS-500 cement silo is supplied together with all necessary silo equipment such as cement screw conveyor with the desired diameter & length, air filter, pressure safety valve, top & bottom level indicators, air fluidization nozzles, pulse valve and cone butter fly valve for manual cement discharging. In case of using the silo for cement terminal or similar application, the screw conveyor can be connected to a loading below to distribute the cement to the trucks.

Parts of AS-500 bolted type cement silo are manufactured by sensitive laser cutting and drilling methods. In the jobsite, parts of cement silos can be assembled easily and sensitively.

Specification

| Silo Capacity | 500 TONS, 385 m3 ( cement density as 1,3 ton/m3 ) |

| Silo Height | 19945 mn |

| Silo Diameter | Ø 6180 mm |

| Quantity Of Silo Legs | 6 |

| Silo Output Diameter | Ø 300 mm |

| Number Of Components | 250 |

| Silo Weight | 28000 Kg |

| Material Of Silo Legs | Ø273 x 12 mm, STEEL PIPE |

| Supports Of Silo Leg | NPL 80 mm CORNER IRON |

| Sheet Metals Of Silo Leg | 20 mm SHEET METAL |

| Conical Part Support Material | 200 mm STEEL C CHANNEL |

| Conical Part Material | ST – 37 ,8 mm SHEET METAL |

| Silo Body Material | ST – 37, 8-6-5 mm SHEET METAL |

| Silo Top Cover Material | ST – 37 , 6 mm SHEET METAL |

| Charging Pipe | 4″ STEEL PIPE UP TO SILO LEG |

| Inner Manhole Is Present | |

| Outer Man Hole Is Present | |

| Silo Roof Includes Handrails | |

| Maintenance Platform Is Present | |

| Structural Analysis Is Made For The Silos And Manufacturing Process Depends On Approved Projects. | |

| painting : 1 layer of anticorrosive paint, 2 layer of final coat epoxy paint, total paint thickness: 140 microns. | |

We also offer Horizontal cement silo. Click here to know more.

Layout