Twin Shaft Mixer

The Twin-Shaft Mixer offer among the most advanced mixing solution, capable of handling from high to zero slump concrete. The twin shaft system mixing consisting two horizontal shafts with arms and paddles moving in counter current; Counter rotating mixing arms and paddle create a spiral shaped vertical and horizontal mix direction, which has ensures to make three dimensional mixing. The twin shaft mixer is the best to make any kind of concrete. The discharge is accomplished by a hydraulic operated gate, which is assembled throughout the length of the mixer vat for fast and complete discharge

Planetary Mixer

This mixer Produce quality concrete with high homogeneity in a very short time. The whole mixer is powered and controlled with a hard surface gear box so, it provides a stable driving. This may cause the planetary mixer one of the best machines to blend concrete out there. This mixer has an extremely high efficiency, attributed through the mixing arms that move on a sophisticated track. The gear box ideally controls these arms. These unique structures offer more efficiency than other machines with regards to concrete mixing. The mixing blades from the planetary mixer comprise of various categories of mixing arms and so ensures great performance. These arms cover the whole mixing area and also this guarantees complete and proper mixing process. The structure from the planetary mixer is uniquely designed. and also this reduced the necessity for maintenance while increasing performance capability. This mixer ideally presents various discharging styles including doors that may be run hydraulically, manually and pneumatically.

Aggregate Waiting Hopper,Water, Cement & Additive Weigher

Water and Cement hopper mounted on independent modular frame structure and weightment can be done by individual electronic load cells.

Automatic Greasing System

Mixer consisting automatic greasing system for shaft seals lubrication to ensure smooth operations.

Aggregate Storage Bin

The aggregate storage bins made from mild steel sheet. The installation of aggregate storage bins very user friendly, as the construction process and the extension of the pre-assembly reduce the installation time of the plant at site. The aggregate storage bins are broaden to facilitate the loading process by loader. The discharge window of aggregate bins opened through pneumatic cylinders.

Control Panel

- The system combines the power of a PLC and dedicated Weighing Modules to provide reliable and accurate control.

- The system can handle up to 4 scales or more; with upto 5 Aggregates, upto 4 Cements, Water & upto 2 Admixtures, being accurately Batched on ‘weight’ basis.

- The system is capable of handling multi-scale, multi-ingredient Batching & Mixing operation, with All necessary Interlocking. Timing. Alarm generation, Event-logging. Recipe & Report generation facility. Software calibration for all scales with password protection.

- The system has Touch Screen display with 3 Serial communication ports & 2 USB port.

- Hgh speed sampling ensures batch to batch accuracy.

- All necessary interlocks are programmed within the system to allow parallel batching and Mixing Operations

- Variety of features incorporated in the system ensures easy and fault free plant operation.

- The Manual Desk equipped with Push buttons, indications and change over switches. Each device in the plant can be operated manually completely by-passing the AUTO system.

Elevating Conveyor

“v” shape embossed rubber conveyor an integrated platform and railing to easy maintenance and cleaning, Conveyor transmitted via direct drive of geared motor.

Weighting Conveyor

The conveyor belt and the partitioned weighing hopper are suspended on 6 Not of electronic load cells for accurate weighing. Weighing conveyor is driven via direct drive of powerful var motor and having subsequent support of Idler roller.

Specification

| Model | AST 20 | AST 30 | AST 45 | AST 60 | AST 75 | AST 90 | AST 120 | |||||

| Output Capacity | 20m3/hr. | 30m3/hr. | 45m3/hr. | 60m3/hr. | 75m3/hr. | 90m3/hr. | 120m3/hr. | |||||

| Mixer Unit | Turbo Pan type mixer/ twin shaft mixer | |||||||||||

| Mixing And Discharge of concrete | Imported Planetary reduction gear box | |||||||||||

| Main mixer drive | 20 HP | 30 HP | 40 HP | 60HP | 60HP | 50HPX2 NOS | 75HPX2 NOS | |||||

| Material Storage Unit | 2X2 Cross Bin | In line four bin feeder | ||||||||||

| Material Storage Capacity | 20m3 | 30m3 | 45m3 | 60m3 | 60m3 | 90m3 | 100m3 | |||||

| Material weighing system – | Digital load cell based weighing of the material in each bin | |||||||||||

| Batch Feeding System | Through inclined belt conveyor/inclined skip bucket | |||||||||||

| Cement Feeding System | Through screw conveyor | |||||||||||

| Water Weighing System | Digital load cell based weighing of Water in tank | |||||||||||

| Ad Mixture dozing System | Digital load cell based auto admixture dozing system | |||||||||||

| Control Panel | Fully automatic PLC Based system | |||||||||||

| Control Cabin | Provided | |||||||||||

| Concrete Discharge Height From GI | 4.0 level from ground | |||||||||||

| Total Connected Power | 52HP | 74HP | 87HP | 120HP | 145HP | 200HP | 275HP | |||||

| Suggested DG Set | 62KVA | 82KVA | 125KVA | 160KVA | 200KVA | 300KVA | 400KVA | |||||

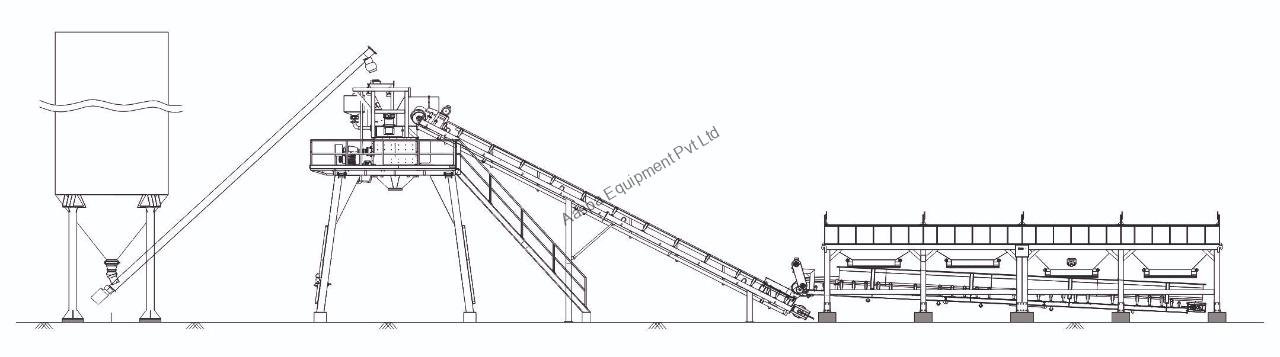

Layout

Salient Features

- Required installation time is very less, due to Modular design.

- Fully Automatic-Electronic operation with PLCPC Control.

- Reliable, Fast and Accurate Electronic Weighine System for major inputs.

- Full service, technical support and spares back-up.

Optional

- Cement/ Fly ash Storage & Conveying System from 20 to 220 MT Capacity

- Microwave Moisture Meter.

- Computer SCADA System with Software.

- Radial Conveyor Belt for Aggregate Feeding

We also offer Mobile Concrete Batching Plant. Click here to know more.