Mobile plants consist of portable shaft mixers that are designed to be moveable and thus are installed on towable chassis with wheels for maximum mobility and quick setup at any place. A mobile concrete batch plant is perfect for temporary construction sites or construction projects where the equipment would only be needed for specific and short portions of the projects. A portable concrete mixing machine can be easily installed and dismantled and as such it requires very minimal preparation or set up before use so it is very convenient.

First of its kind giving a discharge height of 2 meters from the ground level which makes it useful for using a concrete pump as well as transit mixer on-site where the plant is shifted frequently at various site location to meet the concrete mixing requirement. Fully automatic mobile type batching plant with whole plant assembly on single chassis with tow facility makes it effective for use. With the help of a tractor, one can easily move the plant on-site and easy to erect and commission the plant as no need to make foundations and the control panel is also fitted on the same chassis with internal cabling and an inbuilt water tank.

Mobile Concrete Batch Plant Manufacturers are the product of sophisticated engineering work. All units are placed in a smaller area through aesthetic design. They are also preferred by ready mixed concrete companies for major construction projects to which they supply concrete, by establishing a mobile concrete plant within the area of a project to make concrete production only for that project.

Features of Mobile Concrete Batching Plant:-

• Can handle up to 40 mm. down aggregate size.

• Higher accuracy because of higher capacity and more no. of load cells.

• 20 cum/hr concrete output with a mixing time of 90 seconds in continuous operation.

• Mixing through reversible drum mixer.

• Can shift mobile batching plant by toeing with tractor.

• Fully automatic PLC control system HMI.

• Separate weighing for aggregate, water and cement, with higher accuracy.

• Size is very compact & no need make a heavy ramp for dumping material.

• Easy maintenance and low running cost.

Specification:-

| Model | AMP 20 | AMP 25 | AMP 30 | AMP 45 |

| Output Capacity | 20m3/hr. | 25m3/hr. | 30 m3/hr. | 45 m3/hr. |

| Mixer type | Pan type mixer / Planetary mixer / Twin Shaft mixer | |||

| Main reduction gear | imported planetary gear box | |||

| Main mixer drive | 20HP | 25HP | 30HP | 40 HP |

| Material storage system | 2×2 cross bin feeder | |||

| Material Storage capacity | 12m3 | 14m3 | 20m3 | 25m3 |

| Material weighing system | digital load cell based weighing of aggregates cements water and additive | |||

| control panel – | fully automatic PLC based control panel | |||

| concrete discharge height – | 2.1 meter from ground level | |||

| total connected power – | 45HP | 50HP | 58HP | 79HP |

| Suggested DG Set – | 50 KVA | 62 KVA | 82 KVA | 100 KVA |

Optional Accessories of Mobile Concrete Batching Plant

• Computer SCADA System and software

• Fly ash feeding system and storage silos

• Prefab cabin for Control panel

We also offer Reversible Concrete Batching Plant (Drum Type). Click here to know more.

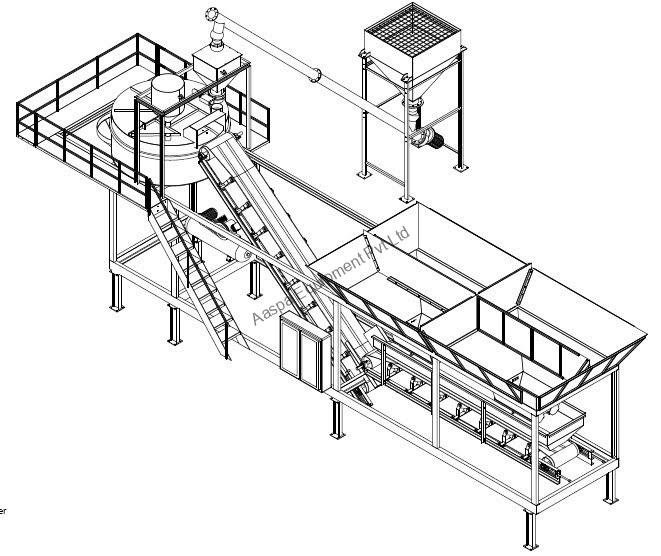

Layout